LASER SYSTEMS

CO2 laser processing machine

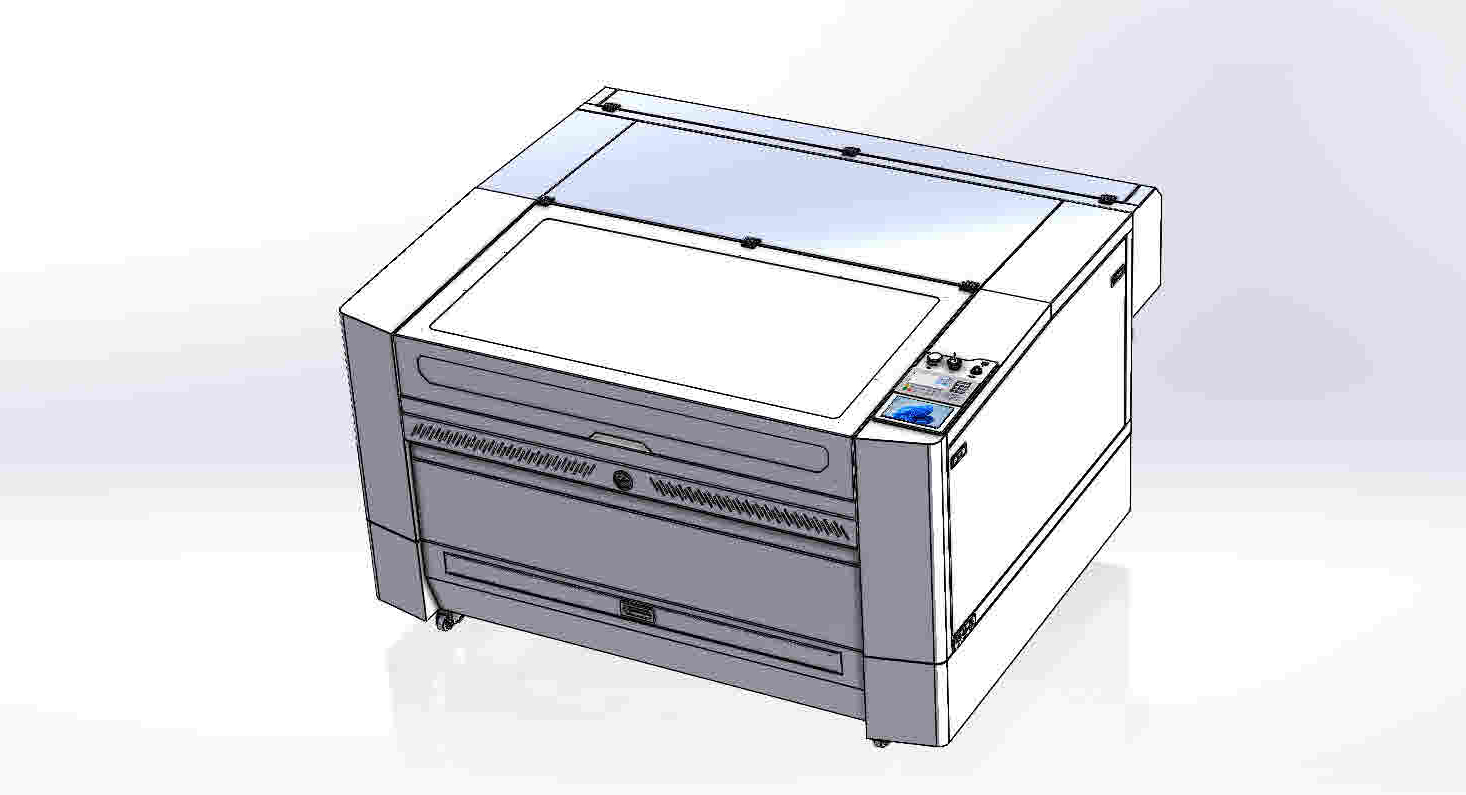

TALENTO4

| Basic Specifications | Options | |

|---|---|---|

| Work area | 600*400mm | |

| Laser | DC 60~100W | RF 30~120W |

| Max processing speed | 900mm/s | 2000mm/s |

| Resolution | 0.003mm | |

| CAM | Dedicated CAM program | |

| Drive system | Micro Step Driver | AC Servo Driver |

| Axis driving method | Timing Belt | Ball Screw |

| Operating system | Windows | Mac |

| Input method | USB, Ethernet | WIFI |

| Assist gas | Air | |

| Vision recognition function | CCD option | |

| Fire detection safety device | Default Installation | |

| Cutable material | wood, acrylic, cloth, paper, leather | |

| Power supply | AC, 220V 50/60Hz 1P | Inquiry for export |

Equipment Features

TALENTO4 is the latest 2024 model that is focused on RMTECH's technology, and is a high-performance and durable piece of equipment.

It supports 600*400(mm) processing areas even in small spaces, and in particular, it can be used efficiently for education and training equipment.

Fire detection devices (patent technology) that can prevent the risk of fire are applied as a standard, and they respond efficiently to smart processes.

It is designed with a high-rigid frame structure and adopts an ACS(anti-corrosion system) structure that protects the instrument even for harmful gas work to maximize precisio.

The laser oscillator can be selected from CO2 laser 30W to 120W depending on the purpose of work.

With the advantage of designing/producing directly, RMTECH can respond immediately to the functions required by users.

-

Application of ACS System

Vibration was minimized by applying a high-rigidity main frame, and distortion was prevented through a heat treatment process at 1100 degrees for 20 hours.

-

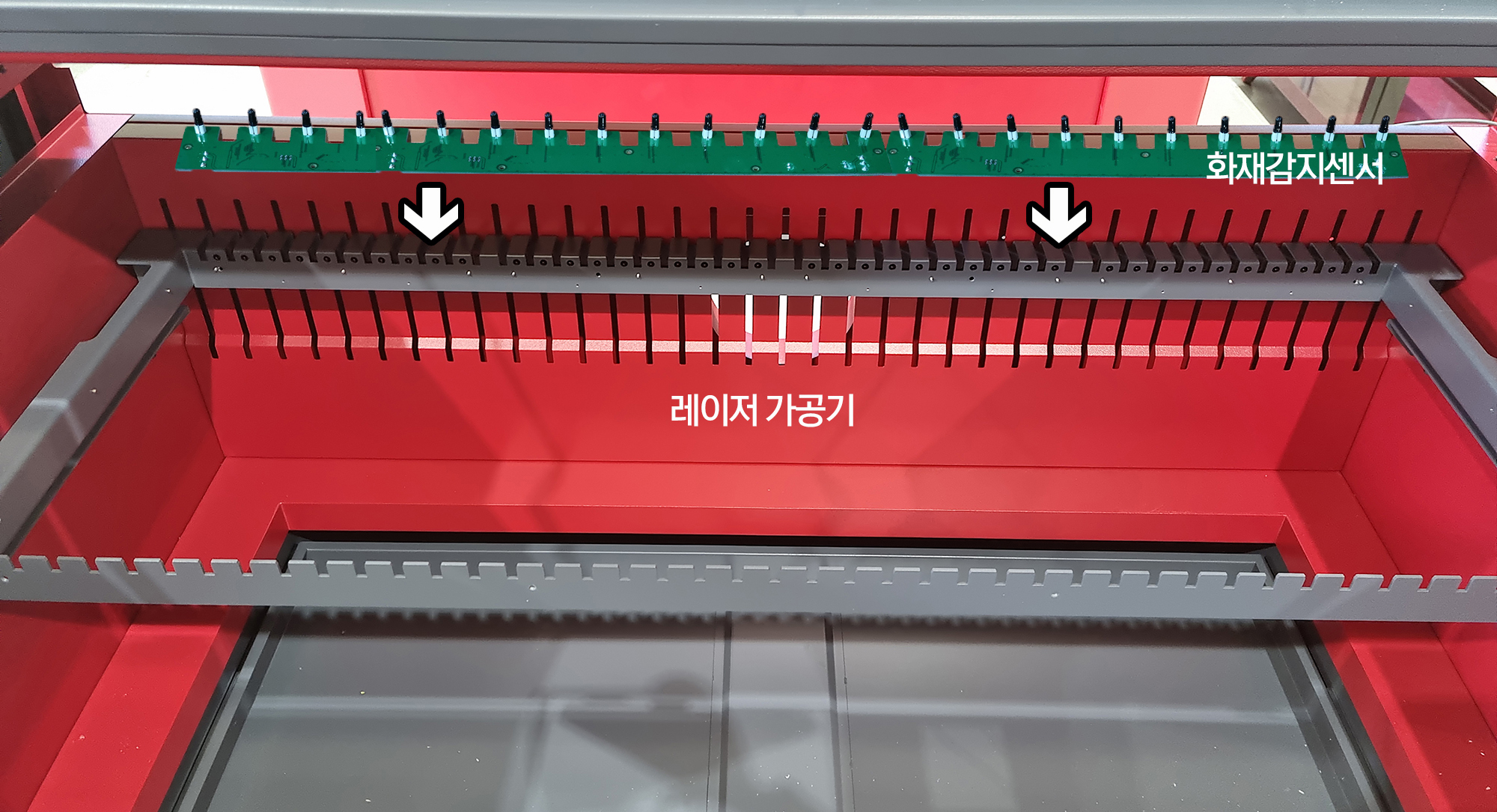

Fire detector

If a fire is detected during operation, the laser power is cut off to prevent the risk of fire. (Fire detection device patent) -

By applying a high-rigidity main frame, vibration is minimized and precision and durability are maximized.

-

Safety cover applied

A safety cover is attached to the front of the processing area, so you can safely check the work progress.

Operation can be set to stop when the safety door is opened. -

Dual wide display

For user's convenience, the existing DSP panel has been upgraded to reduce inconvenience in operation and to make work easier by embedding a PC for operating the equipment.

-

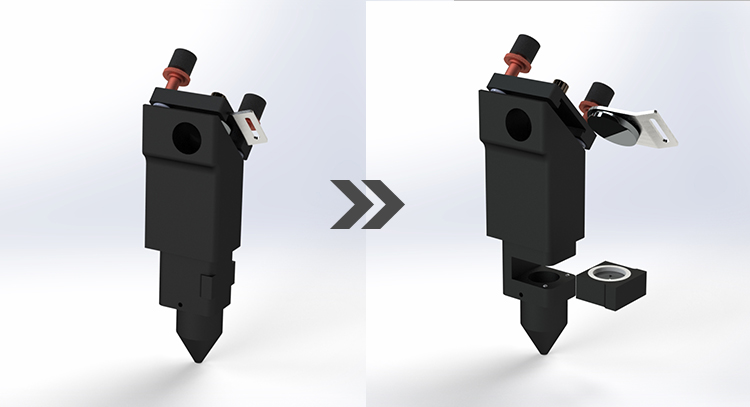

When replacing lenses and mirrors, the Open-Closed method is adopted to minimize cumbersome work and increase convenience.

Option

-

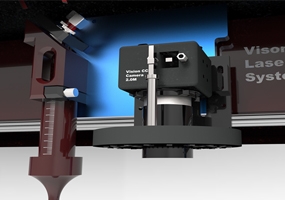

CCD automatic recognition cutting

After using a CCD camera and a dedicated program to print actual images, the image is recognized and precise cutting is performed.

available as an option

-

RF Co2 Laser selectable

Basic application of DC type glass tube CO2 laser,

RF type laser can be selected according to customer's request.

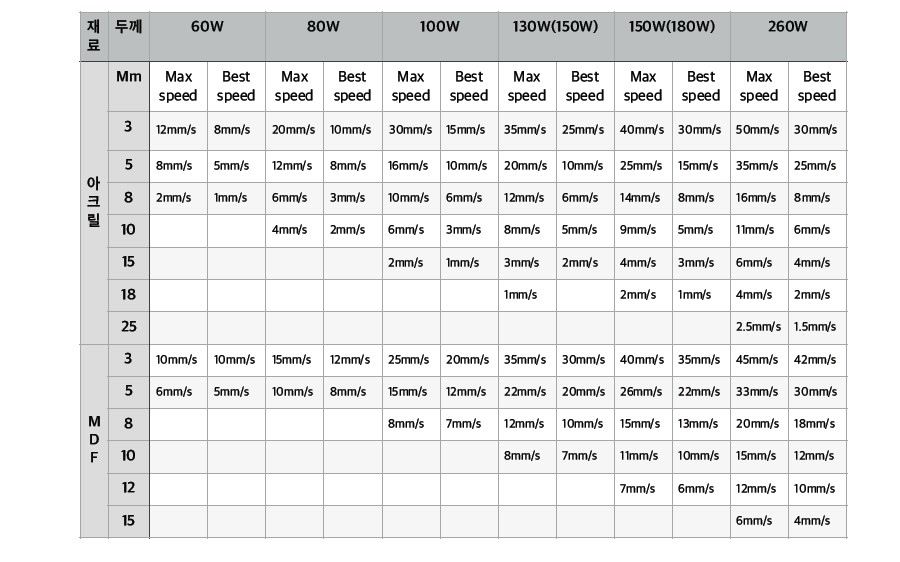

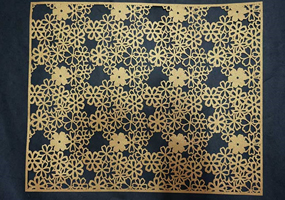

Material Processing Sample

-

acryl

-

paper (Korean paper)

-

leather and fabric

-

metal marking

-

wood

-

glass marking