LASER SYSTEMS

Laser welding machine

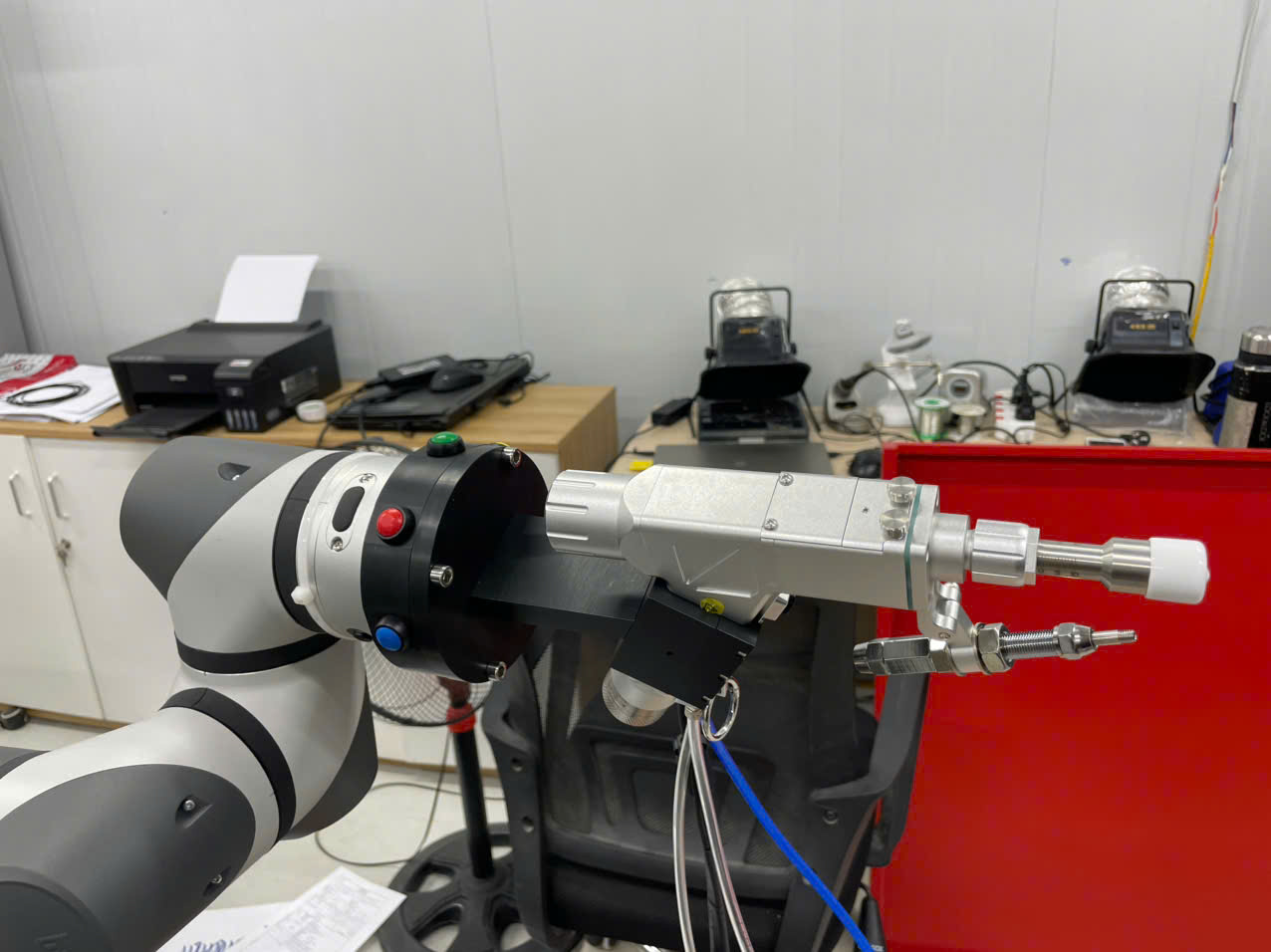

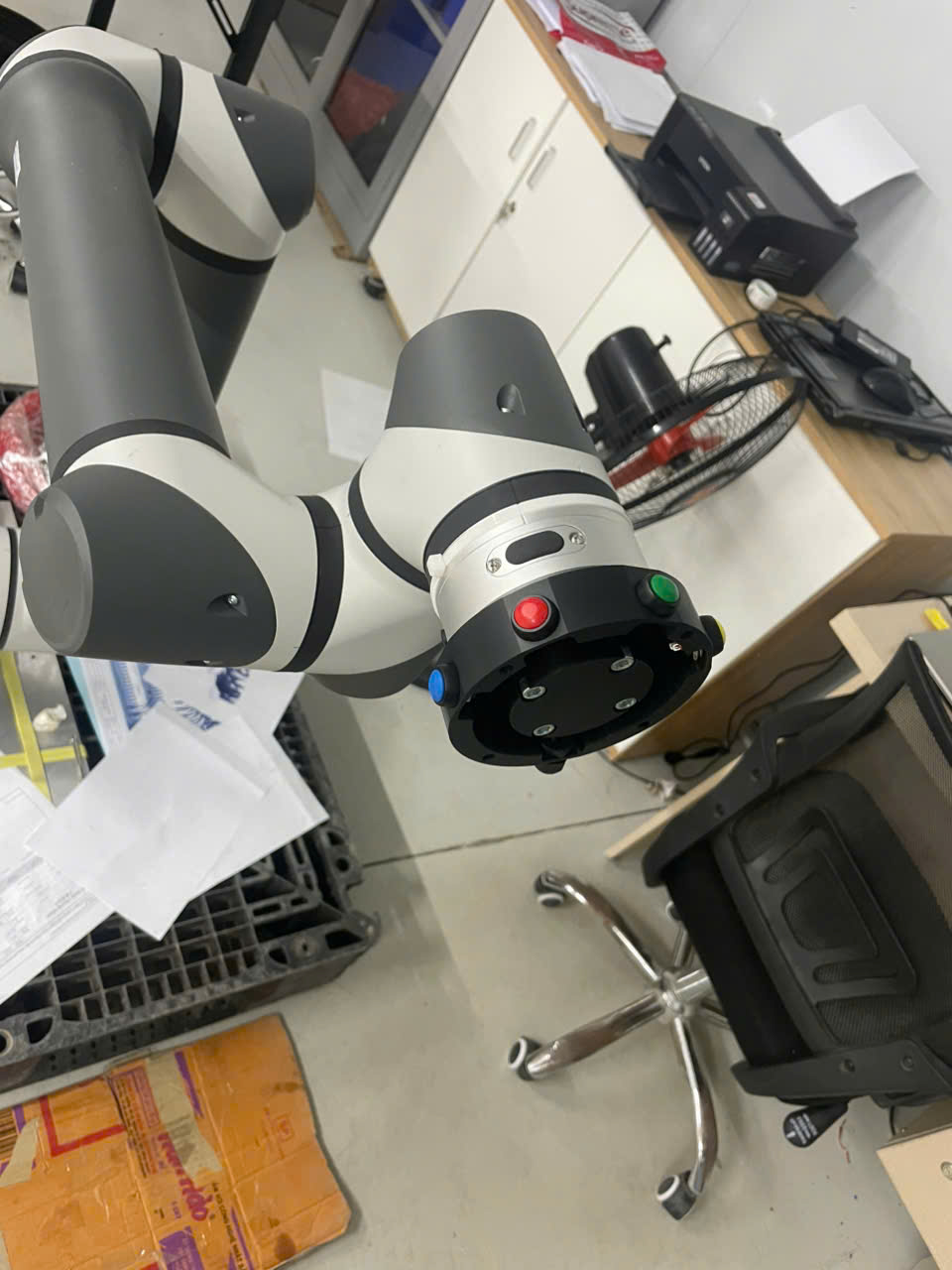

WELMASTER ROBO

| Basic Specifications | Options | |

|---|---|---|

| Laser Power | 1.5~3KW Fiber Laser | 2KW Fiber Laser, 3KW Fiber Laser |

Equipment Features

Precision Welding: Utilizes laser as a heat source for precise welding. Compared to MIG and TIG welding, it offers easier adjustment of welding parameters and less thermal damage, making the welding process simpler.

Ease of Operation: Non-experts can operate the machine with ease. The non-contact welding method ensures consistent weld quality during continuous operations.

Exceptional Productivity: The machine operates at speeds 3 to 5 times faster than TIG and MIG welding, significantly enhancing productivity and operational efficiency.

Clean Weld Surface: Produces exceptionally clean weld surfaces, eliminating the need for post-processing.

Ideal for Thin Materials: Minimizes distortion in continuous welding of thin-sheet structures, maintaining high quality.

Flexible Working Options: Suitable for manual operation, as well as automation with robots or PLC systems.

Smart Factory Compatibility: Equipped with external IO configurations that integrate seamlessly into smart factory environments.

Ease of Automation Integration: Even those without specialized laser knowledge can easily integrate the system into automated setups. Options for collaborative robots are available, allowing for straightforward teaching and integration.